A Foundation Forged in Time, Excellence Through Expertise: Flawless Delivery of the Sibur Direct Contracting Project in Russia

Built on time, enhanced by expertise

- Linyi Machinery Direct signing and supply Successful delivery of zero-gas-consumption blower thermal dryer for the SIBUR PDH2 project, a Russian petrochemical giant

“SIBUR PDH-2 propane dehydrogenation project”

【Project Background】

ZapSibNeftekhim(ZSNKh)Tobolsk

ZapSibNeftekhim (ZSNKh) is Russia's largest hydrocarbon processing plant, accounting for 60% of Russia's polyethylene market and half of its polypropylene market. Its development can be traced back to the Tobolsk Petrochemical Complex (TPC) built between 1974 and 1984. In 1999, TPC was officially incorporated into SIBUR. Construction of ZSNKh started in 2014, a brand-new petrochemical complex built with cutting-edge technology.

In 2020, SIBUR put ZSNKh into full operation. Today, ZSNKh is among the world's top ten polymer producers, with an annual output of 2.5 million tons of polymers and hundreds of thousands of tons of other products, including butadiene, butene-1, MTBE and pyrolysis gasoline. In 2022, ZSNKh became the first plant in Russia to start maleic anhydride production, with an annual capacity of 45,000 tons, filling a gap in the Russian market. In addition, a new polypropylene production plant is scheduled to be put into operation in 2027, with an estimated annual output of 570,000 tons. Including this project, SIBUR's total investment in ZSNKh development projects will reach approximately 1 trillion rubles.

【Project Delivery】

Built on time, enhanced by expertise

Within the agreed delivery timeframe of the project, the Linyi team worked hand-in-hand with the owner's project team to participate in and witness key milestones of the project.

I: Both project teams started on schedule KOM kick-off meeting ,detailed communication on important factors and manufacturing requirements within the cooperation framework, the project entered the design phase

II: The project entered on schedule PIM pre-audit meeting stage, pre-audit experts dispatched by SIBUR headquarters focused on reviewing and inspecting ITP progress, design progress, welding process pre-review, incoming inspection review, and certification matrix details, etc.

III: The project entered the critical stage of production and manufacturing until FAT acceptance key stage. Faced with SIBUR's stringent technical requirements, Linyi, with its professional capabilities and meticulous attitude, completed the review and delivery of hundreds of technical documents, ensuring that the project fully complied with the highest operating standards in the Russian petrochemical industry, and implemented HAZOP safety analysis, with the entire system strictly complying with Russian EAC and GOST standards.

Numerous online and offline communication meetings during the project period ensured project coordination and progress.

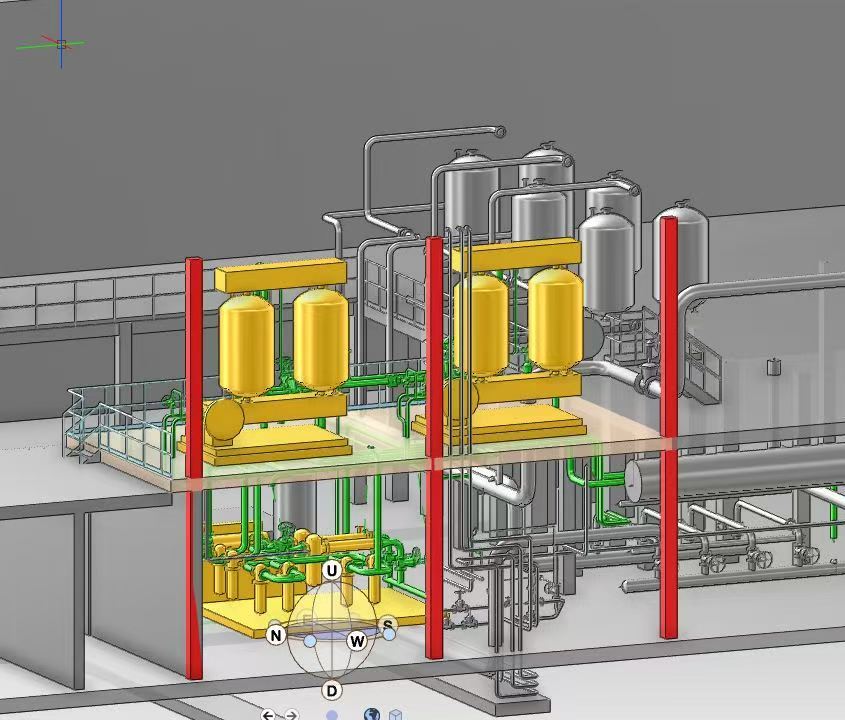

The design of this system breaks through space limitations, using CAESAR II software to accurately model the piping system, comprehensively analyzing pipe end loads, internal pressure, and seismic conditions to ensure the local strength safety and reliability of the main equipment (adsorber and filter).

At the same time, the steel structure was subjected to finite element analysis (FEA) to verify its strength, ensuring that the mechanical properties fully meet the standards. The entire system supply has passed the item-by-item FAT acceptance by SIBUR's acceptance experts and completed the acceptance according to the specific requirements of moisture-proof and rust-proof VCI vacuum plastic film packaging, and is about to be shipped.

Disclaimer: (The above pictures are reproduced from SIBUR's official account. If there is any infringement, please contact us for deletion.)

The project cycle lasted half a year. Through the joint efforts of both teams, the equipment directly signed and supplied to SIBUR, the largest petrochemical owner in Russia, was delivered on schedule, and the shipment ceremony was successfully completed.

Specialized and focused on the field of gas dehydration and purification, we are always striving.

Specialized and focused on the field of gas dehydration and purification, we are always on the path.

Source: International Trade Department

SIBUR,PDH-2 propane dehydrogenation project,Desiccant regenerative blower dryer,Compressed air drying equipment,Gas dehydration in the petrochemical industry

Related news

Recently, our company once again collaborated with an existing customer to custom-design and manufacture a purification unit—the Air Purification System—for a high-purity nitrogen air separation plant. This system will ensure the supply of ultra-clean air, thoroughly free from both carbon dioxide and moisture, thereby meeting the stringent process-gas requirements for cutting-edge lithium-battery material production.

Recently, our company successfully delivered a customized solution for a Chinese military project—an R134a zero-energy-consumption closed-loop heating regeneration dehydration unit with a processing capacity of 66,700 Nm³/h. This unit, with its innovative system design and reliable operational performance, has achieved a significant breakthrough in the deep drying of heavy gas injection and recovery systems (such as R134a).

Based on our deep understanding of new energy technologies, our company can customize equipment tailored to various gas source types—such as PEM, AEM, ALK, chlor-alkali hydrogen production, and methane-hydrogen mixed gases—providing "one-on-one" precision design that ranges from parameter adaptation to process optimization.