Using scientifically reasonable system configuration to safeguard the quality of industrial gases under high temperature and humidity conditions

After the start of the伏天 (a period of hot weather in China), the combination of plum rains and high temperatures causes the relative humidity to often exceed 90%, and the wet-bulb temperature continues to rise. For modern industries that rely on high-quality gases (especially compressed air), the seasonal challenges of high temperature and humidity have arrived. High temperatures further weaken the adsorption efficiency and filtration accuracy of drying equipment, leading to problems such as excess moisture, increased impurities, and fluctuating equipment efficiency. These problems not only threaten production stability but also directly affect product quality and costs. Lino Machinery, based on its deep understanding of core gas purification technologies, builds a full-chain protection system with integrated solutions to build a strong gas quality defense line for enterprises and ensure smooth operation during the summer.

After the start of the伏天 (a period of hot weather in China), the combination of plum rains and high temperatures causes the relative humidity to often exceed 90%, and the wet-bulb temperature continues to rise. For modern industries that rely on high-quality gases (especially compressed air), the seasonal challenges of high temperature and humidity have arrived. High temperatures further weaken the adsorption efficiency and filtration accuracy of drying equipment, leading to problems such as excess moisture, increased impurities, and fluctuating equipment efficiency. These problems not only threaten production stability but also directly affect product quality and costs. Lino Machinery, based on its deep understanding of core gas purification technologies, builds a full-chain protection system with integrated solutions to build a strong gas quality defense line for enterprises and ensure smooth operation during the summer.

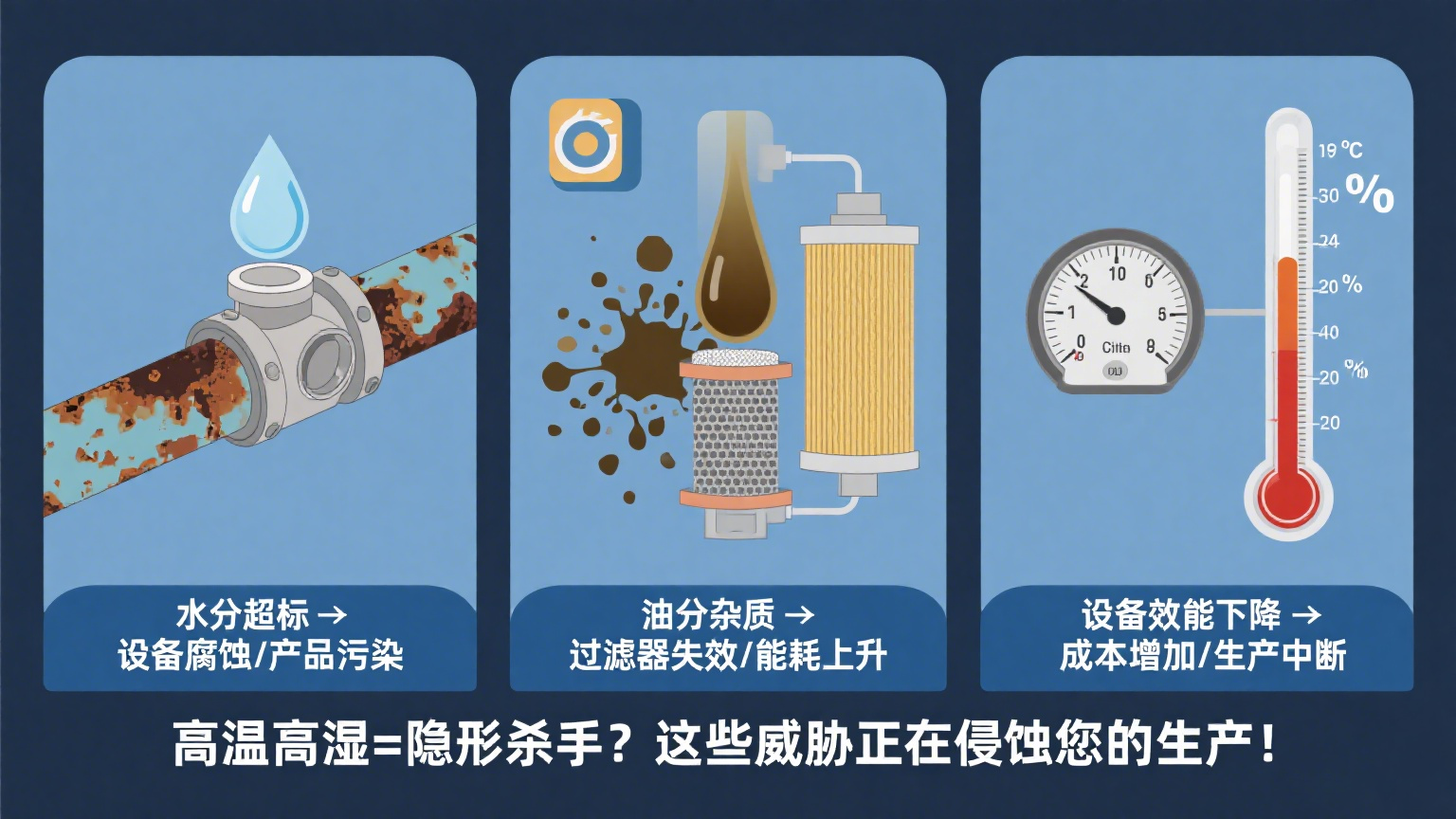

01. High Temperature and Humidity | The "Invisible Killer" of Gas Quality

As ambient temperature and humidity soar, untreated compressed air or process gases face severe challenges:

1. Dew point surges, moisture threat intensifies:

High environmental humidity means that the air drawn into the compressor already contains a large amount of water. Conventional drying equipment may be overwhelmed under extreme operating conditions, leading to increased dew point in the downstream gas. Liquid water precipitates, corroding pipes and valves, damaging precision pneumatic components, and contaminating products.

2. Oil and impurities "take advantage of the situation":

High temperatures accelerate the aging and volatilization of lubricating oil, increasing the content of oil vapor and oil aerosols in compressed air. At the same time, humid and hot environments are more prone to microbial growth. If these oils, particles, and microorganisms are not effectively purified, they will lead to:

• Key process contamination: Such as food and beverage filling, precision electronic component manufacturing, optical lens cleaning, etc., causing product scrap.

• Filter overload failure: Increased impurities accelerate filter clogging, pressure drop increases, and energy consumption rises.

• System corrosion and biofilm: A mixture of water, oil, and dust forms a corrosive mud-like substance; microbial growth forms biofilms, clogging pipes, producing odors, and causing secondary pollution.

3. Reduced equipment efficiency, increased energy consumption and costs:

In high-humidity environments, drying equipment requires more frequent regeneration or increased refrigeration load, increasing the burden on the adsorbent/refrigerant, significantly increasing energy consumption . Purification filters become saturated prematurely due to increased impurity load, increasing replacement frequency and maintenance costs. The overall operating efficiency of the equipment decreases, and production continuity may even be affected due to protective shutdowns.

02. Scientific Configuration | Solving the High-Humidity Problem

In the face of harsh summer operating conditions, single equipment or scattered combinations are often insufficient. Our core advantage lies in how the scientific and reasonable selection and configuration are related to whether the customer's gas usage requirements and energy-saving needs can be met.

1. Scientific configuration as a shield, worry-free summer production:

Customized drying solutions are provided based on the dew point requirements of different industries, Gas quality assurance in high-humidity environments is not a "lone battle" of a single piece of equipment, but a systematic project based on the scientific laws of "pressure - temperature - humidity - flow rate." Lino Machinery's integrated solution follows the core principles of gas purification and breaks through environmental limitations through dynamic control and customized design. It not only meets the gas demand of extreme summer conditions but also reduces equipment investment and operating costs.

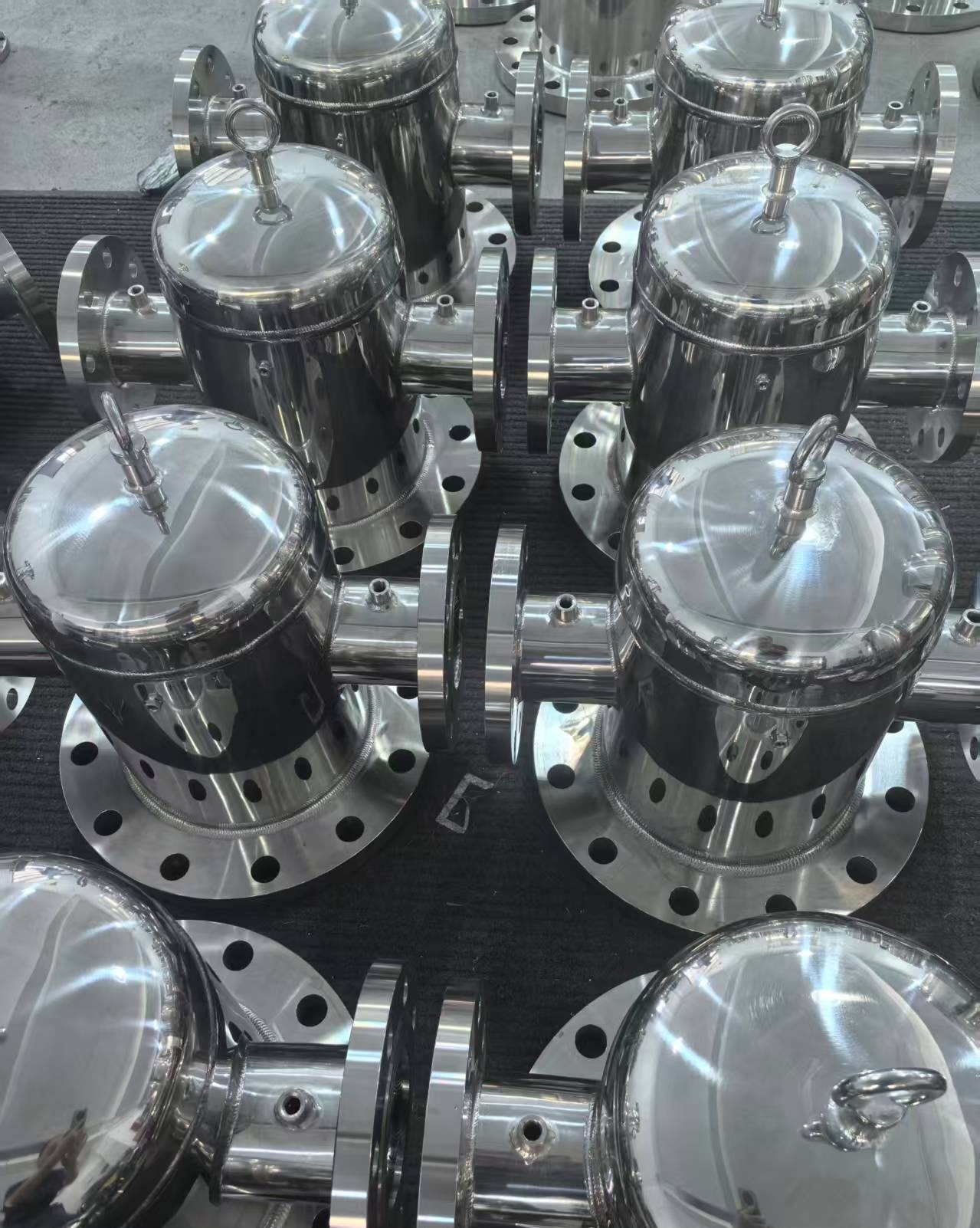

2. Downstream precision purification, intercepting multiple impurities:

Multi-stage precision filtration system Following the "water - oil - dust" layered filtration logic, a multi-stage protection system is built. Filtration equipment can be divided into oil filtration equipment and dust filtration equipment according to the filter medium, and can also be divided into coarse filtration equipment and fine filtration equipment according to the filtration accuracy. Each level of filter specifically removes oil, solid particles, liquid particles, etc., providing pure gas that meets the requirements.

3. "Integrated" intelligent collaboration:

• Intelligent control and monitoring: The system is equipped with an intelligent controller that monitors key parameters (dew point, pressure, temperature, etc.) in real time and adjusts the operating strategy dynamically based on the actual load and environmental changes (such as regeneration cycle adjustment), achieving energy-saving operation while ensuring effectiveness. It provides a remote monitoring interface for convenient predictive maintenance. • Energy-saving logic embedded:

Using "relative humidity assessment" instead of the traditional fixed dew point index, the adsorption regeneration frequency is dynamically adjusted, reducing energy consumption by 20%-30% compared to conventional systems; at the same time, the pipe diameter and pressure drop parameters of the drying and purification units are matched through calculation to avoid “overkill” energy waste.

• Customized solutions for complex needs: For the special requirements of different industries (such as spraying, laser cutting, semiconductors, pharmaceuticals, food) for gas quality, we provide in-depth customized solutions, from equipment selection to precise system configuration.

The drying and purification units are not simply stacked but are rigorous system engineering calculations and matching design . The core of Lino Machinery's integrated gas drying and purification solution lies in "dynamic adaptation," selecting truly reliable and efficient system solutions. It eliminates your "wet" worries, effectively addresses multiple threats such as oil, particles, and moisture, ensuring that the quality of core production gas is as stable as a rock, and protects your summer production with high efficiency, stability, and high quality!

Is your gas drying system ready for the high temperature and humidity challenge?

Contact Lino's professional engineers immediately, and let us tailor-make a customized integrated drying and purification guarantee for you!

Telephone: 0571-88684007/0571-86016039

Website: www.hzlinuo.com

Email: linuo@hzlinuo.com

Gas drying and purification,Gas drying,Gas purification,Adsorption dryer,Freeze dryer

Related news

This article focuses on the core technology of hydrogen drying, providing an in-depth analysis of the principles, characteristics, and selection logic of refrigerated and adsorption drying solutions, offering professional reference for the efficient utilization of hydrogen energy.

Recently, our company successfully delivered a customized solution for a Chinese military project—an R134a zero-energy-consumption closed-loop heating regeneration dehydration unit with a processing capacity of 66,700 Nm³/h. This unit, with its innovative system design and reliable operational performance, has achieved a significant breakthrough in the deep drying of heavy gas injection and recovery systems (such as R134a).

Lino Machinery successfully delivered a zero-gas-consumption hot air drying machine for the Sibur PDH2 project, a Russian petrochemical giant, under a direct signing and supply agreement.