How to choose a refrigerated dryer

old dryer is the abbreviation for freeze dryer, which refers to a new technology and belongs to the air source processing equipment in pneumatic systems. Using refrigerant to exchange heat with compressed air, the temperature of the compressed air is reduced to the dew point temperature within the range of 2-10 ℃. With the continuous development of customers' demand for air source quality, refrigerated dryers are becoming increasingly widely used. Here we introduce the equipment selection of refrigerated dryers for your reference.

1. How many types of commonly used refrigerated dryers are there?

2. What technical parameters are required for selecting a refrigerated dryer?

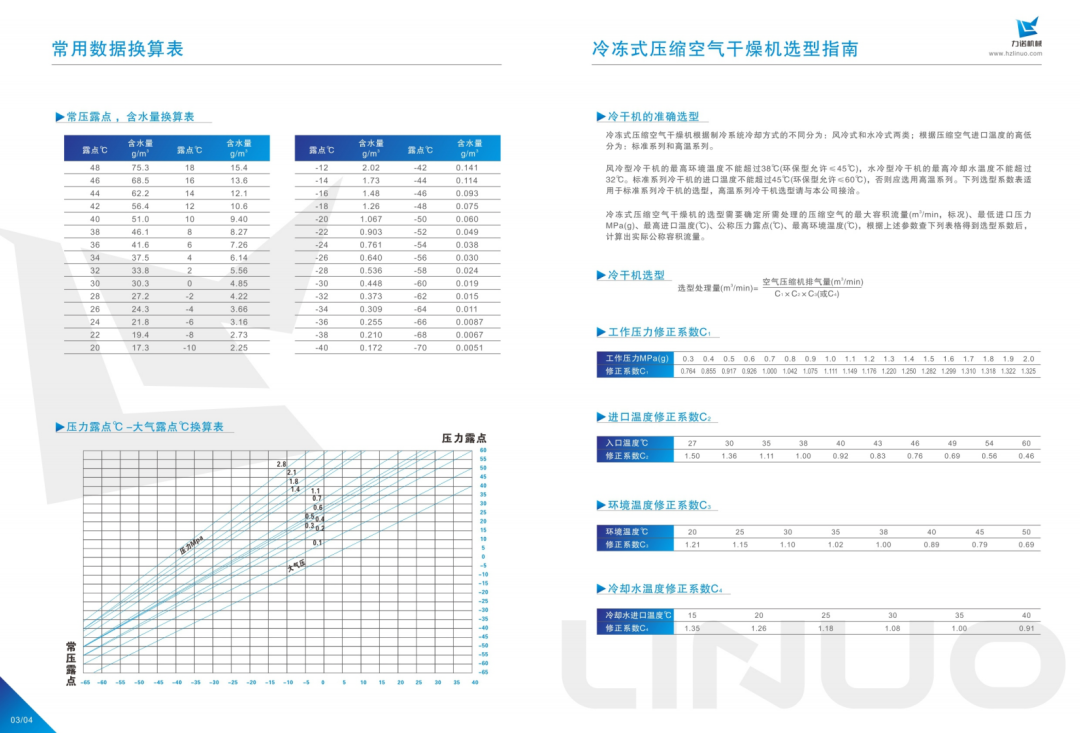

The technical parameters that need to be determined for the selection of a refrigerated dryer include processing capacity (Nm3/min), intake temperature (℃), working pressure (MPa), cooling water temperature required for water-cooled models (℃), and ambient temperature required for air-cooled models (℃). The target parameter of the refrigerated dryer is "pressure dew point" (℃). If "pressure dew point" is marked, relevant conditions (such as intake temperature, working pressure, ambient temperature, etc.) must also be accompanied.

3. What is the "pressure dew point" of a refrigerated dryer (℃)?

On product samples from different manufacturers, there are various markings for the "pressure dew point" of refrigerated dryers, including 0 ℃, 1 ℃, 1.6 ℃, 1.7 ℃, 2 ℃, 3 ℃, 2-10 ℃, 10 ℃, etc. This has caused inconvenience for users in selecting. Therefore, it is of practical significance to explore the "pressure dew point" of the refrigerated dryer and determine how high it can reach. We know that the "pressure dew point" of a refrigerated dryer has three conditional limitations, namely:

① There is a limit on the bottom line of evaporation temperature and freezing point;

② There is a limitation that the heat transfer area of the evaporator cannot be infinitely increased;

③ There is a limitation that the separation efficiency of the "air-water separator" cannot reach 100%. It is normal for the final cooling temperature of compressed air in the evaporator to be 3-5 ℃ higher than the evaporation temperature of the refrigerant; Excessively lowering the evaporation temperature is of no use; Due to the efficiency limitation of the air-water separator, a small amount of condensed water forms water vapor in the heat exchange of the precooler, which can also increase the water content of the compressed air. All these factors combined make it very difficult to control the "pressure dew point" of the refrigerated dryer below 2 ℃. As for the labeling of 0 ℃, 1 ℃, 1.6 ℃, 1.7 ℃, etc., it is often due to commercial advertising elements that outweigh the actual effect, so people do not need to take it too seriously. But under good working conditions, it should be possible to obtain compressed air with a "pressure dew point" of around 5 ℃ through a refrigerated dryer.

4. Is the "pressure dew point" range of 2-10 ℃ for refrigerated dryers a bit too large?

Some people think that the temperature difference of "5 times" between the "pressure dew point" range of 2-10 ℃ marked on the refrigerated dryer is too large? This understanding is incorrect:

① Firstly, there is no concept of 'multiple' between Celsius and Celsius temperatures. Temperature, as a marker of the average kinetic energy of a large number of molecules inside an object, should be calculated from the true starting point, which is the complete cessation of molecular motion at "absolute zero" (0 K); The Celsius temperature scale takes the melting point of ice as the starting point of temperature, which is 273.15 ℃ higher than "absolute zero". In thermodynamics, except for calculations related to temperature concepts, the Celsius temperature scale (℃) should be used as a state parameter, and calculations should be based on the thermodynamic temperature scale (also known as the absolute temperature scale, starting at absolute zero). 2 ℃=275.15K, 10 ℃=283.15K, which is the true difference between the two.

② From the perspective of saturated gas moisture content, compressed air with a pressure of 0.7MPa has a moisture content of 0.82g/m3 at a dew point of 2 ℃ and 1.48g/m3 at a dew point of 10 ℃, with no difference of "5" times between the two;

③ From the relationship between "pressure dew point" and atmospheric dew point, the 2 ℃ dew point of compressed air at 0.7MPa is equivalent to the atmospheric dew point of -23 ℃, and the 10 ℃ dew point is equivalent to the atmospheric dew point of -16 ℃. There is also no "5-fold" difference between the two. According to the above, the range of "pressure dew point" from 2-10 ℃ is not as large as imagined.

5. How to configure the filter correctly for a refrigerated dryer?

The compressed air from the gas source contains a large amount of liquid water, solid dust with different particle sizes, as well as oil pollution, oil vapor, etc. If these impurities directly enter the refrigerated dryer, it will deteriorate the working condition of the refrigerated dryer. For example, oil stains can contaminate the heat exchange copper tubes in the pre cooler and evaporator, affecting heat exchange; Liquid water increases the workload of the refrigerated dryer, and solid impurities can easily block the drainage holes. Therefore, it is generally required to install a pre filter upstream of the air inlet of the refrigerated dryer for impurity filtration and oil-water separation to avoid the occurrence of the above situation. The filtration accuracy of the pre filter for solid impurities does not need to be very high, usually around 10-25 μ, but it is better to have a higher separation efficiency for liquid water and oil stains. Rear filter of refrigerated dryer: For general power gas, a high-precision main pipeline filter is required. When gas requirements are higher, corresponding oil mist filters or activated carbon filters should be installed.

6. What should be noted when matching a refrigerated dryer with a piston air compressor?

A piston air compressor is non continuously supplied with air and generates air flow pulses during operation. The strong and continuous impact of airflow pulses on various components of the refrigerated dryer can cause a series of mechanical damages to the dryer. Therefore, when the refrigerated dryer is used in conjunction with a piston air compressor, a buffer gas storage tank should be installed on the downstream side of the compressor.

7. What are the characteristics of a refrigerated dryer compared to an adsorption dryer?

Compared with adsorption drying, freeze-drying machines have the following characteristics:

① Without gas source consumption, for most gas source users, using a refrigerated dryer saves energy compared to using an adsorption dryer;

② No valve wear and tear;

③ No need to regularly add or replace adsorbents;

④ Low operating noise;

⑤ Daily maintenance is relatively simple, just clean the automatic drain filter screen on time;

⑥ There are no special requirements for the pre-treatment of the gas source and the matching air compressor. A general oil-water separator can meet the requirements of the air inlet quality for the refrigerated dryer;

⑦ The refrigerated dryer has a "self-cleaning" effect on the exhaust gas, which means that the solid impurities in the exhaust gas are relatively low;

⑧ At the same time as discharging condensed water, some oil vapor can also condense into liquid oil mist and be discharged with the condensed water.

Compared with adsorption dryers, refrigerated dryers can only achieve a "pressure dew point" of about 2-10 ℃ for compressed air treatment, so the drying depth of gases is far less than that of adsorption dryers. In many application fields, refrigerated dryers cannot meet the process requirements for gas source dryness. In the technical field, a selection convention has been formed: when the "pressure dew point" requirement is above zero, a refrigerated dryer is preferred, and when the "pressure dew point" requirement is below zero, an adsorption dryer is the only choice.

8. What are the characteristics of domestic refrigerated dryers compared to imported refrigerated dryers?

At present, the hardware configuration of domestically produced refrigerated dryers is not much different from imported ones, and internationally renowned brands are widely used in refrigeration compressors, refrigeration accessories, and refrigerants. In terms of user applicability of refrigerated dryers, they generally exceed imported machines, because domestic manufacturers have fully considered the characteristics of domestic users, especially climate conditions and daily maintenance characteristics, when designing and manufacturing refrigerated dryers. For example, the refrigeration compressor power of domestically produced refrigerated dryers is generally higher than that of imported machines of the same specifications, which fully adapts to the characteristics of China's vast territory and large temperature differences in different regions/seasons. In addition, domestic machines are highly competitive in terms of value and have unparalleled advantages in after-sales service. So domestic refrigerated dryers are quite popular in the domestic market.

Our company not only has its own strong professional team for product research, design, and development, but also has advanced and complete production assembly lines and product testing rooms. We are the first among our peers to obtain ISO9001 quality system certification and production license for special gas dryers. The company adheres to the business philosophy of "striving for excellence and keeping promises", and is dedicated to solving technical problems of gas source systems for customers.

Related news

This article will delve into how the modular dryer achieves a dual leap in energy efficiency and performance, driven by its core principle of "making the most of resources through tiered processing."

Recently, our company successfully designed and manufactured a natural gas molecular sieve dehydration unit for a customer in Tanzania. This equipment will be deployed at a local CNG fueling station to achieve deep dehydration and purification of compressed natural gas (CNG).

For over two decades, Linuo has been deeply rooted in the gas dehydration and purification industry. This time, we are introducing a containerized instrument air compressor station that integrates an air compressor, pressure stabilization tank, refrigerated dryer, adsorption-type deep dryer, and precision filter into one compact unit. This innovative solution offers customers a plug-and-play, highly portable, and reliably performing integrated air supply system tailored to their needs.